Demand is increasing for building materials that support speed, cleanliness, and accuracy. Prefinished wood addresses these priorities directly. This article explores what is prefinished wood?, how it compares to traditional unfinished timber, and why it’s become a preferred solution across both commercial and residential applications.

What Is Prefinished Wood?

So, what is prefinished wood?

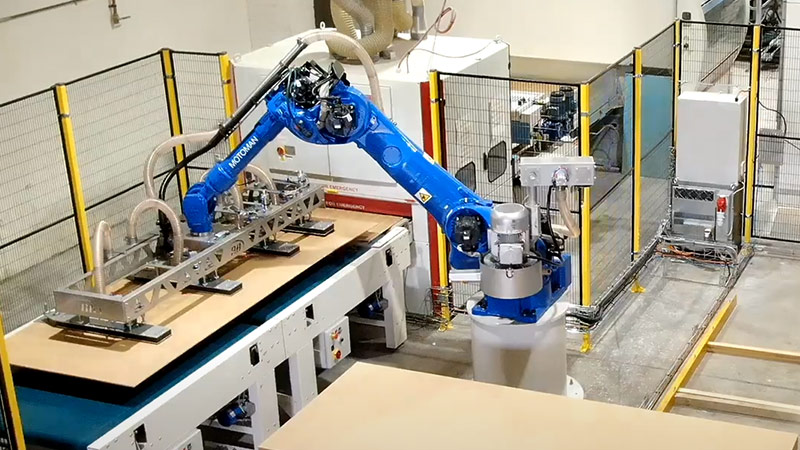

Prefinished wood refers to timber products that have been sanded, stained, and sealed under controlled factory conditions prior to delivery. The process involves precise application of coating systems using technologies such as UV spray lines and automated curing units.

Common applications include hardwood flooring, wall panels, cabinetry, and interior trim. The consistency of prefinishing wood methods reduces on-site labour and minimises surface defects caused by dust, humidity, or improper application.

This method aligns with rising demand for Industrial finishing Australia services—delivering high-performance substrates with stable surface integrity and strong visual finish.

Prefinished vs. Unfinished Wood

When answering the question of what is prefinished wood, it’s important to differentiate it from unfinished wood. In wood finishing solutions, prefinished materials provide immediate advantages at the installation phase. Unfinished timber requires on-site sanding, coating, and drying, introducing delays and variability.

Installation Time

Prefinished wood is installation-ready. No additional treatment is needed post-delivery. In contrast, unfinished timber demands multiple steps on-site—slowing down project schedules and increasing labour costs.

Finish Quality

Factory-controlled environments eliminate inconsistencies. Using a Precision pre-finishing process, finishes are applied evenly with reduced risk of bubbles, streaks, or colour mismatches. On-site applications depend on environmental conditions and worker technique, leading to potential inconsistency.

Durability & Protection

Many prefinished surfaces are UV-cured, providing enhanced resistance against wear, moisture, and light exposure. This makes Industrial pre-finishing a durable solution for high-traffic environments and long-term performance.

Aesthetic Options

Unfinished timber allows full customisation on-site, but prefinished options have significantly expanded in recent years. Advanced colour-matching systems and textured coatings offer a wide range of visual and tactile options.

Why It’s a Game-Changer for Builders

What is prefinished wood and why is it a game changer for builders? Basically, prefinished wood offers significant efficiencies at scale. For commercial builders and contractors, the reduction in on-site finishing time translates directly into faster project turnover and increased operational capacity.

Labour demands are substantially lower. Prefinishing wood eliminates multiple on-site stages, reducing errors, waste, and reliance on specialised trades. With coating systems applied in factory-controlled conditions, the risk of uneven finishes, dust contamination, and coating failures is minimised.

Precision pre-finishing ensures a consistent surface profile and uniform appearance across substrates. This consistency simplifies cost estimation, site coordination, and quality control—particularly useful in multi-dwelling or repeat-specification developments.

Across Industrial finishing Sydney and other high-demand regions, prefinished timber supports tighter project schedules, fewer site variables, and lower remediation costs. For builders operating under deadline or margin pressure, this method provides a reliable, high-yield solution.

Why DIYers Love It

Prefinished wood is a practical option for residential renovators and DIY users. It requires no additional finishing work, specialised spray equipment, or ventilation setup. The product arrives ready for immediate installation.

Because all surface treatments are factory-applied, users avoid common finishing issues like brush streaks, drying delays, or odour exposure. This results in less disruption and a cleaner installation environment—especially in occupied dwellings.

It also shortens completion time. A room fitted with prefinished timber can be used the same day, which is ideal for home improvement projects requiring quick turnaround. From flooring to cabinetry panels, the application range is broad.

Prefinishing wood is especially effective for small to medium renovations where time, simplicity, and clean execution matter most. It’s a low-risk entry point for consumers who want professional-grade outcomes without trade-level complexity.

Conclusion

In this article, we answered the question “what is prefinished wood” and showed some advantages of it for builders and DIYers. You learned that prefinished wood delivers consistent, high-quality finishes through industrial processes optimised for precision and speed. For builders, it streamlines workflow and reduces labour inputs. For home renovators, it simplifies execution while maintaining professional-grade surface quality.

To learn how prefinished materials can integrate into your next project, contact Enekor to schedule a technical consultation.